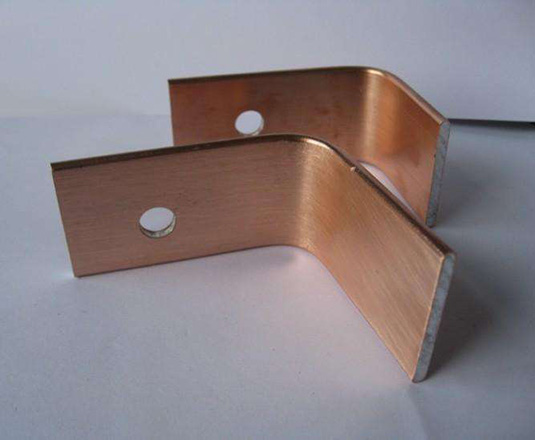

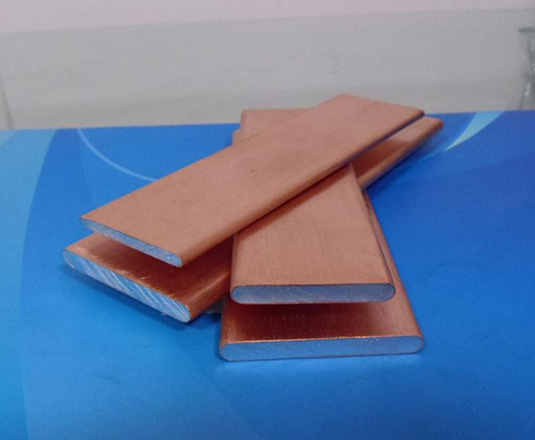

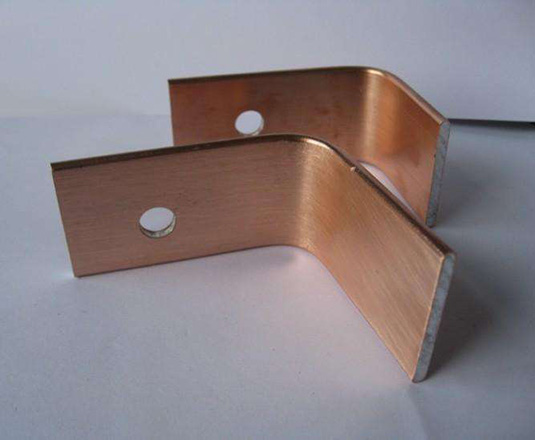

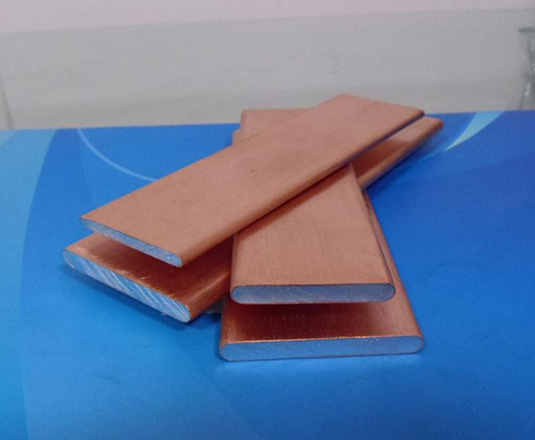

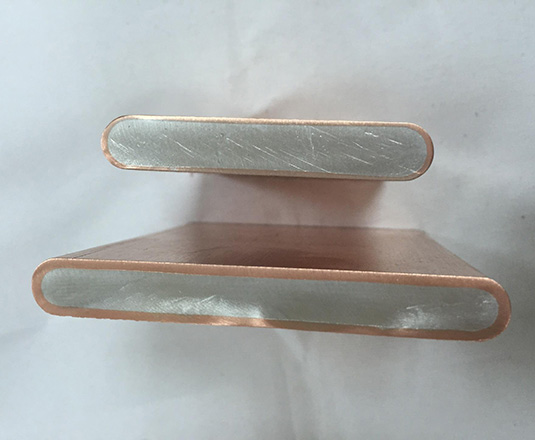

Copper clad aluminum busbar

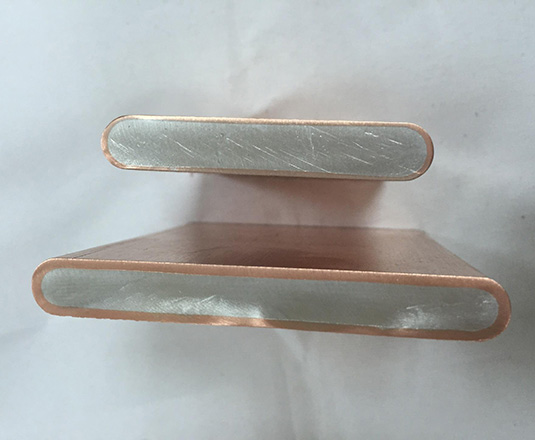

The outer layer of the copper clad aluminum bar is copper and the inner layer is aluminum, usually used in electric equipment.

- Material:1060 Aluminum,T2 Copper

- Specification:3mm-15mm

- Application:High and low voltage distribution cabinet,Complete switch,Busway,Electrolytic cell

The copper clad aluminum busbar is a composite conductive material whose outer layer is copper and the inner core is aluminum.It is widely used in electric control power distribution equipment. As a high current current carrying conductor, it is designed to replace copper busbars and is easy to process and use like copper busbars.

According to the "skin effect" principle, the current is concentrated on the surface of the conductor, so the copper of the inner core of the pure copper busbar does not play a large role.The copper clad aluminum busbar is based on this principle to replace the copper inside the copper row with aluminum, which is combined into a copper clad aluminum conductive material through a series of complicated processes.

The copper clad aluminum busbar makes full use of the characteristics of strong corrosion resistance, low contact resistance, and large current carrying capacity of the copper busbar. It also has the advantages of light weight and low cost of the aluminum busbar.The advantages of copper and aluminum are fully utilized, and their respective shortcomings are overcome. At the same time, they have been widely used in the electrical control and distribution equipment industry. It can save 40-50% of the conductor costs for customers.

The main application areas of copper clad aluminum bus bars are: high-frequency, intermediate-frequency heating equipment, combined battery connections, railway tracks and other conductors, crane sliding contact wires; busway systems, busbar high-voltage, low-voltage busway; switch cabinets (low-voltage, medium- Pressure, high voltage), switchboard, electric control box.

Product technical indicators (cross-sectional area ratio of copper layer 20%, copper layer quality ratio 45%)

1. DC Resistivity: 0.0248 Ω • m,

2. Current Carrying Capacity: 86% of pure copper

3. Elongation: 12%-35%

4. Tensile Strength: 80MPa – 200MPa (depending on soft or hard state)

5. Density: 3.94g / cm³

6. Yield Stress: 44MPa-54MPa (soft state), 152MPa-179MPa (hard state)

7.Modulus of Elasticity: 71GPa

8.Thermal conductivity: 0.58 Cal / Cm / Sec

According to the "skin effect" principle, the current is concentrated on the surface of the conductor, so the copper of the inner core of the pure copper busbar does not play a large role.The copper clad aluminum busbar is based on this principle to replace the copper inside the copper row with aluminum, which is combined into a copper clad aluminum conductive material through a series of complicated processes.

The copper clad aluminum busbar makes full use of the characteristics of strong corrosion resistance, low contact resistance, and large current carrying capacity of the copper busbar. It also has the advantages of light weight and low cost of the aluminum busbar.The advantages of copper and aluminum are fully utilized, and their respective shortcomings are overcome. At the same time, they have been widely used in the electrical control and distribution equipment industry. It can save 40-50% of the conductor costs for customers.

The main application areas of copper clad aluminum bus bars are: high-frequency, intermediate-frequency heating equipment, combined battery connections, railway tracks and other conductors, crane sliding contact wires; busway systems, busbar high-voltage, low-voltage busway; switch cabinets (low-voltage, medium- Pressure, high voltage), switchboard, electric control box.

Product technical indicators (cross-sectional area ratio of copper layer 20%, copper layer quality ratio 45%)

1. DC Resistivity: 0.0248 Ω • m,

2. Current Carrying Capacity: 86% of pure copper

3. Elongation: 12%-35%

4. Tensile Strength: 80MPa – 200MPa (depending on soft or hard state)

5. Density: 3.94g / cm³

6. Yield Stress: 44MPa-54MPa (soft state), 152MPa-179MPa (hard state)

7.Modulus of Elasticity: 71GPa

8.Thermal conductivity: 0.58 Cal / Cm / Sec

GET A QUOTE

| Thickness*Width | Cross-sectional area() | Ampacity(A) |

| 3×15 | 43.06 | 158 |

| 3×20 | 58.06 | 205 |

| 3×25 | 73.06 | 255 |

| 3×30 | 88.06 | 310 |

| 4×30 | 116.56 | 340 |

| 4×40 | 156.5 | 450 |

| 4×80 | 316.56 | 750 |

| 5×40 | 194.62 | 470 |

| 5×50 | 244.62 | 610 |

| 6×50 | 292.26 | 655 |

| 6×60 | 352.26 | 780 |

| 6×80 | 472.26 | 1045 |

| 6×100 | 592.26 | 1305 |

| 6×140 | 832.26 | 1820 |

| 8×60 | 466.24 | 890 |

| 8×80 | 626.24 | 1190 |

| 8×100 | 786.24 | 1500 |

| 8×135 | 1066.24 | 2025 |

| 8×160 | 1266.24 | 2400 |

| 8×175 | 1386.24 | 2620 |

| 8×200 | 1586.24 | 3000 |

| 10×60 | 578.8 | 1000 |

| 10×80 | 778.5 | 1330 |

| 10×100 | 978.5 | 1700 |

| 10×120 | 1178.5 | 2040 |

1.What is the difference between copper clad aluminum busbar and copper to aluminum transition plates?

Copper clad aluminum busbar is based on aluminum and coated with copper,The copper to aluminum transition plates is partially copper-clad on the surface of the aluminum layer, and can be either single-layer copper or double-sided copper.

2.What are the application fields of copper clad aluminum busbar?

The application areas of copper clad aluminum busbar include:Bus duct, switch cabinet, control cabinet, transformer, high and low voltage distribution cabinet, various copper and aluminum transition joints, etc.

Copper clad aluminum busbar is based on aluminum and coated with copper,The copper to aluminum transition plates is partially copper-clad on the surface of the aluminum layer, and can be either single-layer copper or double-sided copper.

2.What are the application fields of copper clad aluminum busbar?

The application areas of copper clad aluminum busbar include:Bus duct, switch cabinet, control cabinet, transformer, high and low voltage distribution cabinet, various copper and aluminum transition joints, etc.