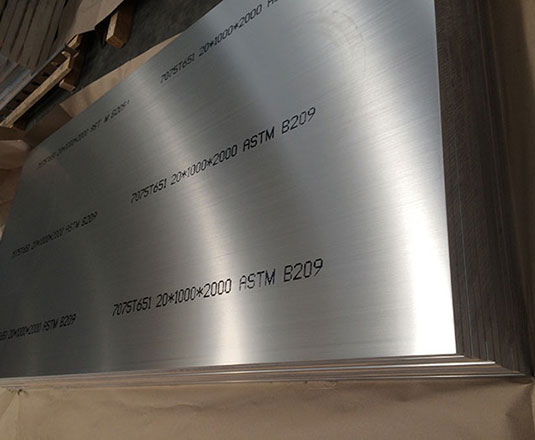

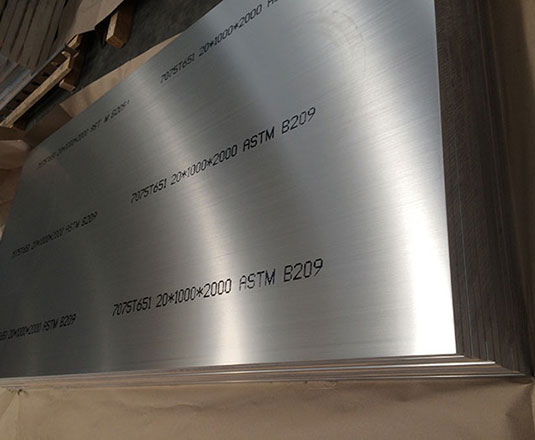

7075 Aluminium Plate Sheet

7075 aluminum plate manufacturer/Thickness:1-200mm/Global exports/Customizable super width and thickness/aircraft aluminum plate

- Material:7075 aluminium alloy

- Specification:Thickness:1-200mm,Max Width:2600mm

- Application:Aircraft,Mold

The chemical element of 7075 aluminium plate is Al-Zn-Mg-Cu, which belongs to super-hard aluminum. It is widely used in the aviation industry such as aircraft manufacturing. The 7075 T651 temper is the best product among 7075 aluminum plates.

Features:

1.Good plasticity after solution treatment, especially heat treatment strengthening effect.

2.It has high strength below 150 ° C and has particularly good low temperature strength.

3.Common anti-corrosion performance and good mechanical properties.

4.High strength and abrasion resistance, far better than mild steel.

Our advantage:

1.It can produce 7075 ultra-wide and ultra-thick aluminum plates, with internal stress relief and no deformation during cutting. The widest is 2600mm and the thickest is 200mm.

2.Using a super wide 2650mm six-high cold rolling mill, the product profile is better, the accuracy is higher, and the performance is more stable.

3. All ultra-wide and thick 7075 aluminum plates are detected by ultrasonic waves, which can effectively ensure no trachoma and impurities.

Mechanical properties:

Tensile strength: 525Mpa

Yield strength: 503Mpa

Elongation: 11%

Volume expansion coefficient: 68 * 10ˉ6

20 ℃ volume conductivity IACS: 33

20 ℃ resistivity NΩ.M: 52.2

Modulus of elasticity E / G: 71pa

Hardness HB: 150

Density kg.m-3: 2820

Application:

It is used to manufacture aircraft structures and other high-stress structural parts that require high strength and strong corrosion resistance, such as aircraft upper and lower wing wall panels, stringers, bulkheads, etc.

Features:

1.Good plasticity after solution treatment, especially heat treatment strengthening effect.

2.It has high strength below 150 ° C and has particularly good low temperature strength.

3.Common anti-corrosion performance and good mechanical properties.

4.High strength and abrasion resistance, far better than mild steel.

Our advantage:

1.It can produce 7075 ultra-wide and ultra-thick aluminum plates, with internal stress relief and no deformation during cutting. The widest is 2600mm and the thickest is 200mm.

2.Using a super wide 2650mm six-high cold rolling mill, the product profile is better, the accuracy is higher, and the performance is more stable.

3. All ultra-wide and thick 7075 aluminum plates are detected by ultrasonic waves, which can effectively ensure no trachoma and impurities.

Mechanical properties:

Tensile strength: 525Mpa

Yield strength: 503Mpa

Elongation: 11%

Volume expansion coefficient: 68 * 10ˉ6

20 ℃ volume conductivity IACS: 33

20 ℃ resistivity NΩ.M: 52.2

Modulus of elasticity E / G: 71pa

Hardness HB: 150

Density kg.m-3: 2820

Application:

It is used to manufacture aircraft structures and other high-stress structural parts that require high strength and strong corrosion resistance, such as aircraft upper and lower wing wall panels, stringers, bulkheads, etc.

GET A QUOTE

|

Tensile strength (Mpa) |

Yield Strength (Mpa) |

Elongation% |

Bulk expansion coefficient m3(.m3.k)ˉ1 |

20 ℃ volume conductivity IACS |

20 ℃ resistivity NΩ.M |

Elastic ModulusE/Gpa |

Hardness HB |

Density kg.mˉ3 |

| 525 | 503 | 11 | 68*10ˉ6 | 33 | 52.2 | 71 | 150 | 2820 |

| Typical alloy | Material condition | Thickness(mm) | Width(mm) | Length(mm) | Typical products |

| 7075 Aluminum Plate | F、O、T6、T651、T7451、H112 | 1-500 | <2600 | <8000 | Mold, shoe mold, precision parts, etc. |

1.What are the most common temper of 7075 aluminum sheet?

7075 T6 and 7075 T651 are the most common of 7075 aluminum plates.

2.What is the hardness of 7075 aluminum sheet?

Generally, the Brinell hardness of 7075 T6 aluminum plate with a thickness of 10mm or more is 150HB.

3.What are the market applications of 7075 aluminum plate?

The market applications of 7075 aluminum plate include high-end mobile phones, blow molds, ultrasonic plastic welding molds, golf heads, shoe molds, paper molds, foam molding molds, dewaxing molds, templates, fixtures, mechanical equipment, mold processing, and high-end production Aluminum alloy bicycle frames and other fields.

4.What is the difference between 7075 aluminum plate and 6061 aluminum plate?

(1) The alloy composition is different. The 7075 aluminum plate is a super-hard aluminum plate, and the hardness is much higher than 6061 aluminium plate.

(2) Different applications, 6061 alloy aluminum plate requires various industrial structures with certain strength, weldability and high corrosion resistance, such as manufacturing trucks, tower buildings, ships, trams, furniture, mechanical parts, precision machining, etc. Tubes, rods, shapes, plates. 7075 aluminum plate is used to manufacture aircraft structures and other high stress structural parts and molds that require high strength and strong corrosion resistance.

5.What are the advantages of 7075 aluminum plate application in aircraft?

(1) The 7075 aluminum alloy has good plasticity after solution treatment, and the heat treatment strengthening effect is particularly good. It has high strength below 150 ° C and particularly good low temperature strength.

7075 T6 and 7075 T651 are the most common of 7075 aluminum plates.

2.What is the hardness of 7075 aluminum sheet?

Generally, the Brinell hardness of 7075 T6 aluminum plate with a thickness of 10mm or more is 150HB.

3.What are the market applications of 7075 aluminum plate?

The market applications of 7075 aluminum plate include high-end mobile phones, blow molds, ultrasonic plastic welding molds, golf heads, shoe molds, paper molds, foam molding molds, dewaxing molds, templates, fixtures, mechanical equipment, mold processing, and high-end production Aluminum alloy bicycle frames and other fields.

4.What is the difference between 7075 aluminum plate and 6061 aluminum plate?

(1) The alloy composition is different. The 7075 aluminum plate is a super-hard aluminum plate, and the hardness is much higher than 6061 aluminium plate.

(2) Different applications, 6061 alloy aluminum plate requires various industrial structures with certain strength, weldability and high corrosion resistance, such as manufacturing trucks, tower buildings, ships, trams, furniture, mechanical parts, precision machining, etc. Tubes, rods, shapes, plates. 7075 aluminum plate is used to manufacture aircraft structures and other high stress structural parts and molds that require high strength and strong corrosion resistance.

5.What are the advantages of 7075 aluminum plate application in aircraft?

(1) The 7075 aluminum alloy has good plasticity after solution treatment, and the heat treatment strengthening effect is particularly good. It has high strength below 150 ° C and particularly good low temperature strength.